Leading Smart Health Manufacturing

Integrated R&D, design, production and sales technology enterprise specializing in intelligent personal care hardware and therapeutic products.

State-of-the-Art Manufacturing Facility

Located in the innovative hub of Shenzhen, our advanced facility combines cutting-edge technology with comprehensive production capabilities.

Strategic Location

Shenzhen Hi-Tech Industrial Park, China

Prime location with access to world-class supply chain and logistics infrastructure

Manufacturing Area

3,000+ Square Meters

Comprehensive production facility with dedicated zones for each manufacturing process

Expert Team

100+ Skilled Professionals

Dedicated R&D, engineering, production, and quality assurance specialists

Streamlined Production Workflow

From raw materials to finished products, our integrated manufacturing process ensures consistent quality and efficient production.

Injection Molding

Precision plastic component manufacturing

SMD Assembly

Surface mount device placement

Final Assembly

Component integration & assembly

Function Testing

Comprehensive functionality validation

Aging Test

Long-term reliability testing

Quality Control

Final quality inspection

Pack & Storage

Professional packaging & warehousing

Advanced Testing & Production Equipment

State-of-the-art machinery and testing equipment ensuring superior product quality and reliability.

Salt Spray Testing Machine

Corrosion resistance testing for metal components and surface treatments

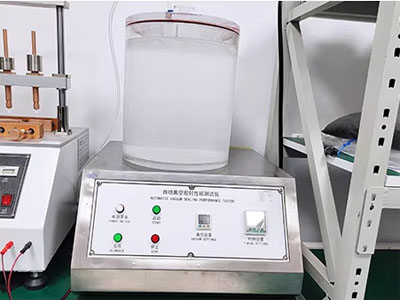

Vacuum Sealing Performance Tester

Waterproof and airtight performance validation for sealed products

Withstand Voltage Tester

Electrical safety testing to ensure product compliance with safety standards

Key Lifespan Testing Machine

Durability testing for buttons and mechanical components lifecycle

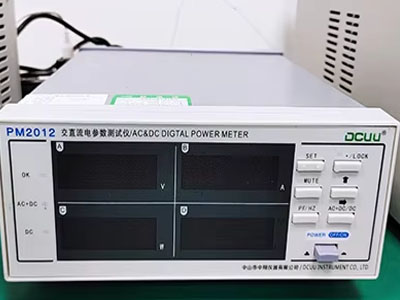

AC and DC Parameter Tester

Comprehensive electrical parameter measurement and validation

Constant Temperature Wet Test Chamber

Environmental testing under controlled temperature and humidity conditions

Battery Comprehensive Tester

Complete battery performance, capacity, and safety testing

Injection Molding Machine

High-precision plastic component manufacturing with automated controls

Scalable Production Excellence

Robust manufacturing capacity with flexible delivery solutions to meet diverse market demands.

Monthly Production Capacity

Scalable manufacturing output

48H Ready Stock Strategy

Fast delivery guarantee

Peak Season Guarantee

Seasonal demand management

3x capacity scaling for holiday seasons

Rapid scaling for urgent orders

Supply Chain Synergy

Integrated ecosystem management

Schedule Your Factory Visit

Experience our manufacturing excellence firsthand. Book an on-site tour or virtual facility walkthrough.